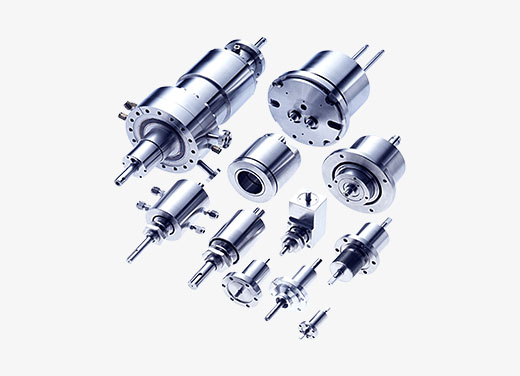

Ferrofluidic Vacuum Feedthroughs

From semiconductor manufacturing to aerospace industry, Ferrotec's Ferrofluidic Vacuum Feedthroughs are globally recognized for good sealing performance in harsh environments. We are committed to providing diverse types of Ferrofluidic Seals, Vacuum Rotary Feedthroughs, integration of seal assembly and parts, and the ultimate rotary sealing solutions for vacuum environments.

Multi-shaft Seal Feedthroughs

Multi-shaft seal feedthroughs are mainly designed for robotic arms which are wildly applied into semiconductor processing and production industries. Ferrotec (China) also provides 10-8Torr ultra-high vacuum sealing devices.

Motor-Integrated Ferrofluidic Vacuum Feedthroughs

Ferrotec's Motor-Integrated Ferrofluidic Vacuum Feedthroughs combining a hermetic Ferrofluidic vacuum feedthrough with a high precision motor and controller to offer a compact and high-performance integrated sealed rotation system. This design eliminates the integration challenges and potential mechanical failure points when customers are connecting discrete components. Typical applications that coaxial drive motorized feedthroughs are used for include MOCVD, thin film, optical coating, ion beam deposition, ion beam etch, physical vapor deposition, Sputtering, ion implantation, and any other application where a motor is used, particularly where servo motor is necessary.

Hollow-shaft Seal Feedthroughs

Hollow-shaft Seal Feedthrough contains a clamp that connects the user shaft and the shaft of the sealing device through an O-ring. A typical application is sputtering equipment, inside which includes rotating unit for electron, neural or ion injection, rotating rack, X-ray and Optical machine. Ferrotec (China) provides multiple types of Hollow-shaft Seal Feedthrough such as Through-Hole and Flange type. Customized products with special design or design without clamps are also available.

Solid Ferrofluidic Seal Feedthroughs

We provide multiple types of solid ferrofluidic seal feedthroughs for all occasions such as: mini type, through-hole type, flange type, and heavy-load type. Except for the small-diameter shaft, the power assembly and the user’s mounting part of the shaft have a standard key slot. Besides, multiple combinations such as flat surface, threaded connection and hole connection can be customized designed and manufactured. Our standard metric seal feedthroughs are also applicable for occasions like high temperature, heave-load, and water-cooled form in high speed applications. (Except for some mini-sized and through-hole ferrofluidic seals.)